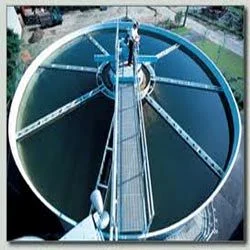

Lamella Clarifier

Our Commonly manufacturing steps of the Lamella Clarifier are as follows:

- The process typically begins with design and engineering. Engineers create blueprints and specifications based on the requirements of the Lamella Clarifier, considering factors such as flow rate, suspended solids concentration, and available space.

- Once the design is finalized, the next step involves procuring the necessary materials. This may include structural components like steel or aluminum for the clarifier plates, as well as mechanical components such as pumps, motors, and valves.

- Fabrication involves the actual construction of the Lamella Clarifier according to the design specifications. This step may involve cutting, bending, welding, and assembling the various components to form the structure of the clarifier.

- Before the Lamella Clarifier is put into operation, it undergoes rigorous quality assurance and testing procedures. This ensures that the clarifier meets the required performance standards and is free from defects or flaws that could affect its functionality.

The manufacturing process of the Lamella Clarifier begins with meticulous design and engineering efforts aimed at creating a robust and efficient system. Engineers work closely to develop blueprints and specifications that align with the specific requirements of the project, considering factors such as flow rates, suspended solids concentrations, and available space. Once the design is finalized, the procurement of materials commences, sourcing everything from structural components like steel or aluminum for the clarifier plates to mechanical parts like pumps and valves. This stage sets the foundation for the subsequent fabrication process, ensuring that all necessary elements are in place for seamless construction.

Fabrication marks a critical phase in the manufacturing of the Lamella Clarifier, where the theoretical design transforms into a tangible structure. Skilled workers utilize a variety of techniques, including cutting, bending, welding, and assembly, to bring the design to life. Precision and attention to detail are paramount during this stage to ensure the integrity and functionality of the clarifier. Once fabrication is complete, the clarifier undergoes rigorous quality assurance and testing procedures to validate its performance and reliability. Only after passing these tests with flying colors does the Lamella Clarifier proceed to installation, ready to deliver efficient separation of solids from liquid streams in various industrial applications.

Application:

- Purifies water by removing suspended solids efficiently.

- Clarifies process water for manufacturing industries effectively.

- Separates solids from wastewater in mining operations economically.

- Treats municipal water for safe consumption reliably.

- Removes impurities from process water effectively.

- Clarifies water used in chemical production processes efficiently.

- Improves water quality by removing suspended solids effectively.